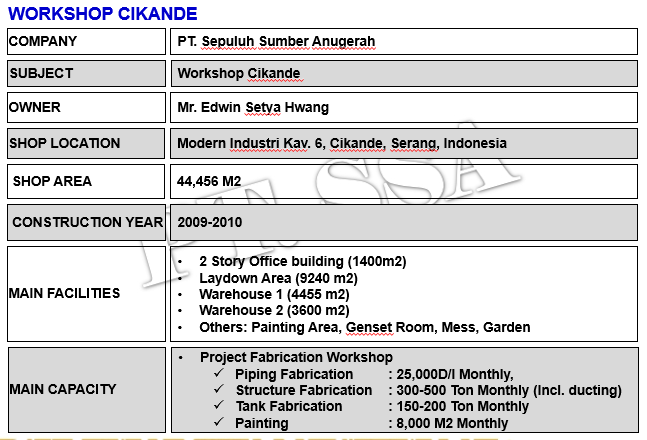

SSA owns two workshops to support various projects. They are located in Kawasan Modern Industri Cikande Serang. Our major workshop has total area of 44.456 m2 and other one is 7.200 m2.

The workshop is designed to flawlessly carry out fabrication process for Tank, Piping, Steel structure and ther mechanical work that SSA is specialized in at workshop, SSA has driliing machine 600 ton, gantry crane with lifting capacity of 10 ton, rolled machine with capacity up to 20 mm thickness, engine welding machine, plasma cutting machine, forklift, TMC with lifting capacity 10 ton and 25 ton mobile crane.

SSA is the first company in Indonesia to own Automatic Welding Machine for spool piping fabrication. SSA has two of these Automatic Welding Machine that with International patent. SSA can produce spool piping NPS from 2”to 40” with productivity more than 300 DI per day per machine with zero rejection rate.

SSA workshop procedures are aligned with that of ISO 9001. On top of this, SSA adds on procedures and qualifications that we’ve learned from global standard clients such as Exxon Mobile, Chevron, Shell and BP. A smaller workshop produces corrugated pipes. SSA workshop’s capacity to produce quality items is certainly the best in Indonesia. Cikande, Serang, Banten – Indonesia.